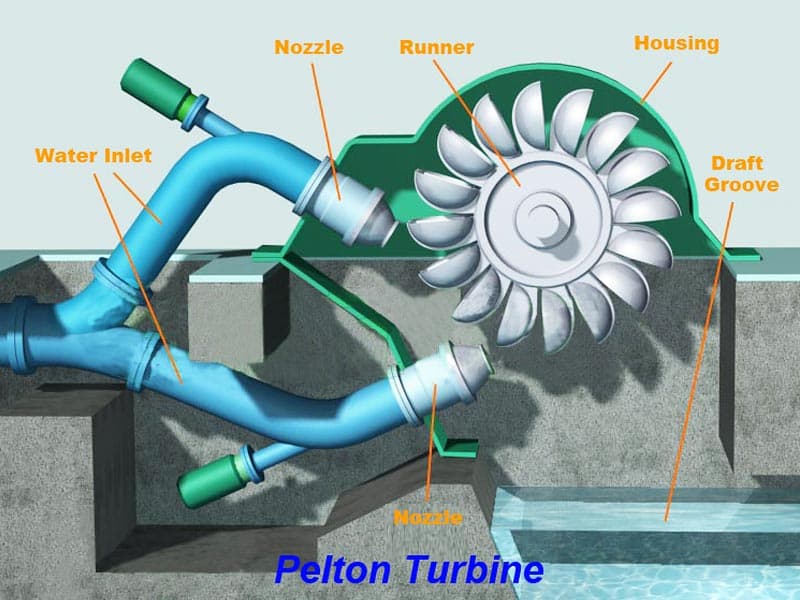

Pelton turbines harness the kinetic energy of water and visually resemble a traditional water wheel. Firmametal can position them vertically or horizontally. Usually two jets are preferred for horizontal positioning and four or more can be used in vertical positioning. In horizontal positioning, two rotors rather than one can be placed on the same shaft that drives a single generator. The highest efficiency is obtained when the speed of the rotor container is half of the water jet. In such case, if operated at 60-80% of full load, more than 90% of the potential energy lost by the water passing through the turbine can be converted into mechanical energy. Pelton turbines are implemented in large hydroelectric systems above 150 m gross head. This turbine can also be used in lower heads in micro hydraulic systems.A Pelton turbine with a small diameter and rotating at high speeds can be used on heads under 20m to generate 1 kW power. High power and low flow rate cause substantial loss of speed, which increases the extent of the turbine.

In such turbines, the energy of the water is first passed through a suitably-shaped pipe to turn it into a water jet at the outlet and then converted into kinetic energy. This jet is then ejected on to cup-shaped rotor blades. The geometry of the cups is designed to absorb the energy of the water jet at the highest rate. Vertical dividing plates passing through their center ensure that the water is distributed in two parts.