Professional Firms

Firmametal operates in the fields of Casting, Hot Forging, Cold Forging, Stamping and Machining of finished products in partnership with the professional firms comprising the intergroup group of companies. Transferring its accumulated knowledge to these firms, Firmametal cooperates on each product, controlling each process step by step and implement necessary know-hows, technologies and propriety processes. By extending its ecosystem to the firms it supplies finished products to, Firmametal is able to adopt a clear, transparent and learning-focused business understanding.

Corporate Approach

Primarily, Firmametal puts each of its products through an evaluation process. After the design and development requirements of a product have been determined, Firmametal then works out how to best manufacture this item in cooperation with the professional firms comprising its overall ecosystem.

Firma establishes business relationships with its group’s professional firms understanding that they will cooperate in every phase of production, including the supply of unprocessed materials, production techniques, the exchange of know-how, process management, die-mold design, the various production stages, production equipment, shared quality control assurance, work completion, statistical measurement, delivery, inspection and R&D.

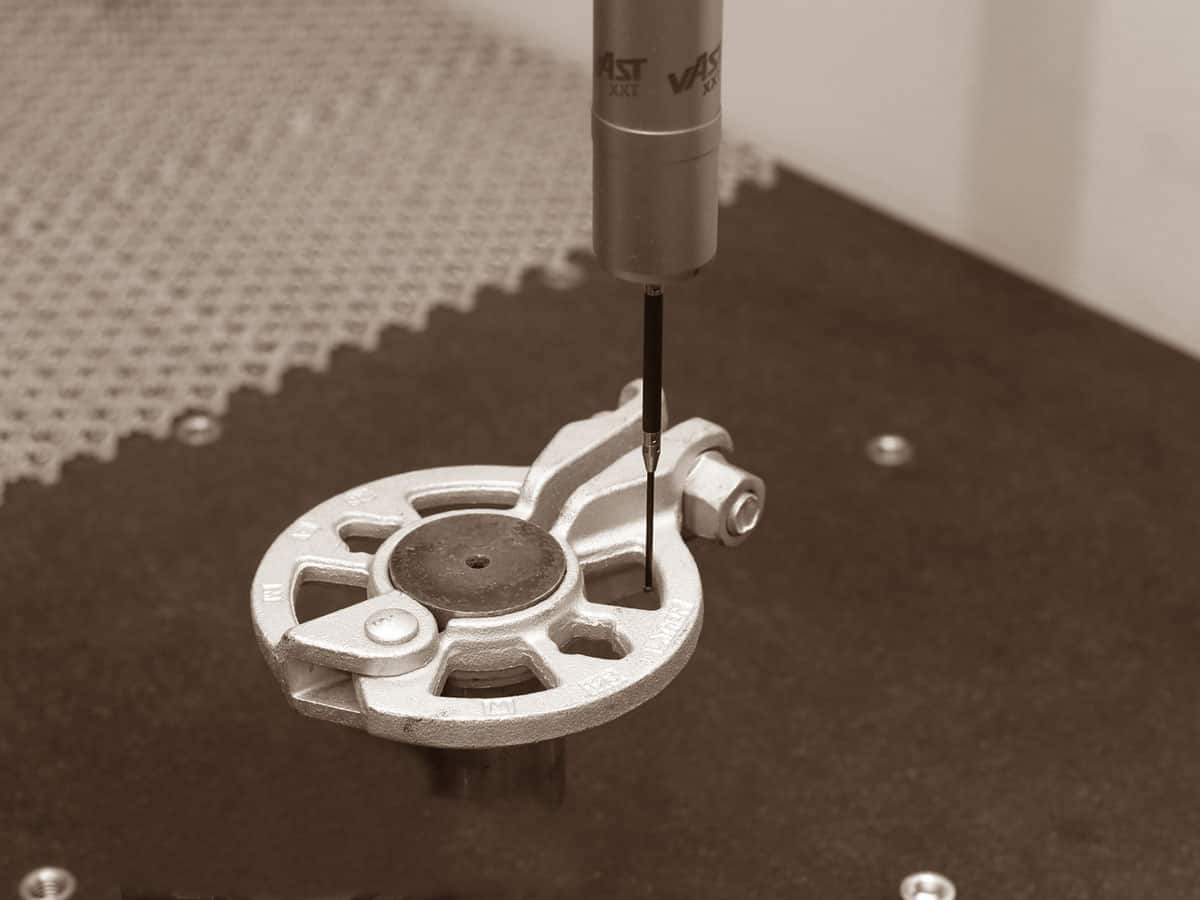

Quality and Assurance

The firms included in the Firma ecosystem have all undergone a preliminary qualification and are all supervised. For each new product, a pre-assessment meeting is held with the engineering, business administration, and quality assurance units of the firms involved, under the leadership of a representative of senior management. Progress is followed by detailed analyses, meetings, business plans and engineering reports. The most technical aspects of the work cannot be transferred to any other firm at any time, and Firmametal is included at each step. All production experiences are collected, studied and shared with Firma. Each manufacturer utilizes an open communication model, working as if it was part of Firmametal’s own company. In other words, Firmametal’s production rules and regulations are spread to in each enterprise comprising its ecosystem.

Production Phases

The first phase is the initial work undertaken by design engineers. Die-mold technologies are developed here. Next is the production phase. The production prescriptions that consists experience and know-how stipulated by Firmametal are supplied to manufacturing with the product in question being formed in accordance with these prescriptions. The control phase follows. The entire quality control process is organized by Firmametal. The product is now reassessed to ascertain whether there are any details to be developed or modified following trials and tests. Firmametal’s R&D expertise works with manufacturing here. The R&D studies are concluded and the product is then subjected, again, to its tests. Following this phase, a production prototype is approved and Firmametal’s senior management can now initiate purchasing operations. The materials required manufacturing the product and from where to source these materials are determined by Firmametal. As the quality assurance system operates at each step, each product’s different standards are applied, again, during mass production.