Interview With Faruk Özer – CEO Firma Metal Intergroup Company

“EXPERTS IN MATERIALS SCIENCE”

Firma Metal operations

Firma Metal is an organization with an operations and manufacturing structure built on our expertise in materials science and manufacturing technologies. We have an emphasis on heavy industry, which we can break down into the segments of heavy machinery, energy and power generation and defense industry.

Don’t we get involved in light industries? Well, yes, we do, but we consider it as heavy industry as well. Firma Metal’s areas of expertise include metal and its derivatives, precision processing such as molding and casting, and welded assembly.

What is “Materials Science?

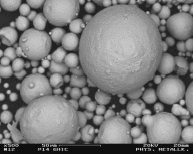

Think of all the engineering disciplines put together. Everything starts with a material. There is a process in physics called “nucleation and propagation”, which refers to the formation and development of an atom in nuclear form, its propagation and completion. Engineering starts with materials. Starting from ore itself develop to manufacture a hand-operated device or machinery in excellence, or an aircraft engine, or a precision stainless-steel medical tool, or a transistor for radars, or a radio component – it all products derivatives of the material science. That is a brief description of materials science.

What is “Materials Design?

When we talk about the design of materials, we are talking about thousands of materials that started out with physics and chemistry and were then developed through a comprehensive process of labor and research. Even making wood composites from polymers is part of this field. The thousands of types of steel in existence were developed as a result of this kind of work. They were developed according to need and demand. Therefore, it was natural that materials science would evolve alongside the materials that were designed to serve people and processes. Designing the materials comes into focus at this point. If you are going to design a product, you need materials. You can either choose one that is readily available or build on the existing options to develop a new material. This is what is known as materials design. For example, let’s say you are developing a turbine for marine operation and it has a corrosion-resistant part. But if this part works in freshwater, it needs to be designed with different materials for the sea and vice versa.

Human resources profile

We have a core staff of engineers with expertise in materials sciences. Universities now distinguish between “industrial” and “physical” metallurgy. In Turkey, materials engineering is delivered as part of one of these branches. This is not the case in other parts of the world. There is now a separate engineering branch that examines the science of materials in detail, covering industrial metallurgy, physical metallurgy and materials science. We need to employ engineers with expertise in these three fields. We also need mechanical engineers who use these materials… engineers who know how these materials are used and can work out how best to put them to use. We have a great need for them too. There is also a role played by manufacturing engineers. We use industrial engineers less. But they are essential when we want to achieve better efficiency levels in our manufacturing processes. We employ manufacturing engineers with expertise on technical data. Materials science, mechanical engineers and manufacturing engineers: That is the essence of what we do.

We have a major problem in Turkey, because there are not enough new engineers coming through the system. Engineering is a precise discipline and you need practical experience as well as academic education. There is a need for engineers with industry experience, who have found their application areas and have practical knowledge obtained at university or elsewhere. They are not easy to find in Turkey.

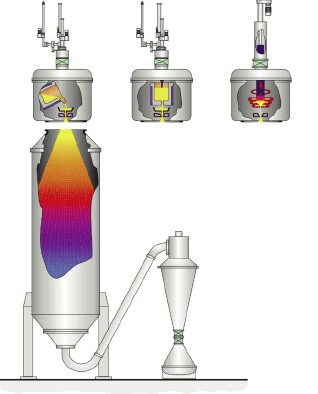

Methods of manufacturing

Our method of manufacturing is very different. We used to develop and implement processes entirely relying on our own R&D. This was the case in the 80s and 90s. However, developments in Turkey and the rest of the world led us to re-evaluate our aims. In an era of global integration, we think that R&D and manufacturing focused on a limited area is not the answer. We now need a holistic view. We have now developed a unique manufacturing model including twenty partners in what we refer to as our ecosystem.

Work cycle in the eco-system

We spent years engaging in major work across various industrial segments and this gave us the opportunity to familiarize ourselves with the industrialists and their areas of work. We learnt who was who. We learnt what we could do with who. We learnt which investments and machinery create higher added value. In Turkey, these capacities are often underused. We thought about how to tackle that. Firma Metal is rooted in science and implementation, so we developed a system for solving the issues and producing the products. We called this system an “Eco Partnership”. We partnered with two companies for the ductile iron foundry that we needed. Relationships are as important as technology in this industry. Without effective collaboration, communication and management systems, or if there are insufficient controls, the system doesn’t work. We’ve always moved along in twos: Two foundries, two steel casting companies, two forging companies… we always have two partners. We wanted to safeguard our work by using two partners who could collaborate and learn from each other and also act as an extra form of system control. We also have some partners from the precision processing sector. There are different degrees of precision welding assembly: light welding, heavy welding and lighter machinery for the heavy machinery industry. We created a great team addressing each of these areas. There are now twenty companies in the team. A logistics and customs specialist is also an eco-partner. When we accept a company as an eco-partner, that doesn’t mean we just hand over the job. We guide them into it. Eco-partnership allows us to keep full control over the organization and establish our own monitoring systems. We also work like this with our financial consultant. To sum up, we bring together various companies under our management, integrate our areas of work into their systems and help them acquire the skills required for the manufacturing operations and to make the system work. We achieved success by developing products from scratch with R&D and taking them all the way to production. We were careful not to lose focus and partnered with larger companies. We closed down some of their departments. It’s this team that enabled us to present them with different finished products.

Being flexible

We started by recruiting locally for two reasons. Firstly, our greatest strength lays in the land we know best. What I mean is that it’s here that we built up our experience, we know the people, we communicate better, we know how to make and manage contacts well. We took our strength from home and now we are competing on a global scale. Now we are in the process of global integration, which is an absolute necessity for us. We have started working on how to enter the international arena, in order to safeguard against domestic political risks and economic crises. Regardless of whether Turkey joins the EU, we want to be able to operate in Europe, and we are investing and working towards this goal. We are thinking about how we can collaborate with European companies, take them into our ecosystem, develop our ecology in Europe, about how we can create manufacturing alternatives, produce higher quality products. In order to make this happen, we are developing the right networks and making investments in various areas. For example, we are in contact with several European universities We are developing a major product at Istanbul Teknopark. By developing this product, we are trying to make an impression and create a certain perception. We are working on sample projects to show that this product can be made in Turkey with advanced technology. We are trying to expand our base by developing high-tech products in collaboration with foreign universities.

All products critical components

When we developed our ecosystem, we asked ourselves the question “What are we?” We are experts in materials science. We know how to shape materials. We excel in manufacturing technologies. We can compete on a global scale in manufacturing technologies. Quality itself is not enough for a competitive edge; you need to use engineering economies to achieve maximum quality with low outlay and low prices. If you say, “this is expensive because it’s really well made”, it doesn’t make you competitive. That’s how we achieve parity with our European competitors. We’ve now reached a level of technology and efficiency that allows us to compete with India or Poland. Other former Eastern Bloc companies can’t compete with us. They can compete in terms of cost, but not in terms of quality. What do I mean? We don’t compete on main products. We compete on our capability to develop main products. Europe has a history of 250 years working in main products. Take the manufacture of turbines for example… It requires accumulated knowledge. They have built up experience in planning and manufacturing from delivering thousands of projects. Rather than positioning ourselves as a direct competitor, like Chinese companies or collaborating with Chinese companies to manufacture at low costs, I say, “I manufacture better. Let’s be partners.” As we excel at materials science and technologies, they are happy to partner with us. What is a partnership? Eco-partnership. We define our profit margins separately and that’s how we dominate the market. I don’t compete with a partner company. Every one protects each other. For certain products, we make the company’s critical components or make more than one product for them as a team of solution partners.

Areas of investment

The main thrust of our investments is towards developed countries. This is not just about costs – our purpose is to gain a foothold in the market by showing that we can work closely with partners already operating in it, collaborate with other professionals to provide swift resolutions to problems and become an established member of chambers of industry and commerce. We are focused on long-term collaboration. Their own countries are going through a period in which subsidiary industries are being lost. They can’t compete in terms of cost. There is a massive loss because no second generation has followed on. We can fill this gap. There is a great synergy from our collaboration with other companies with expertise in manufacturing technologies. We decided to invest in Europe. We will do the main production and labor-intensive work in Turkey and complete the final production with advanced robotics processes in Europe. To do the finishing at a distance where we can intervene, to be able to store there, to have logistics connections for the system, to be able to deliver low-cost transportation operations within our own structure – with cargo trains, containers, depots logistics to safeguard production against the impact of global crises and show our partners that we are able to do so.

There are three requirements for competing on a global scale: Good price, premium to excellence in quality, job on time. If any of these are lacking, you are out of the competition. As far as we are concerned, that is where the future is.